What Makes UV Boards Stand Out from Other Materials?

Key Features of UV Boards

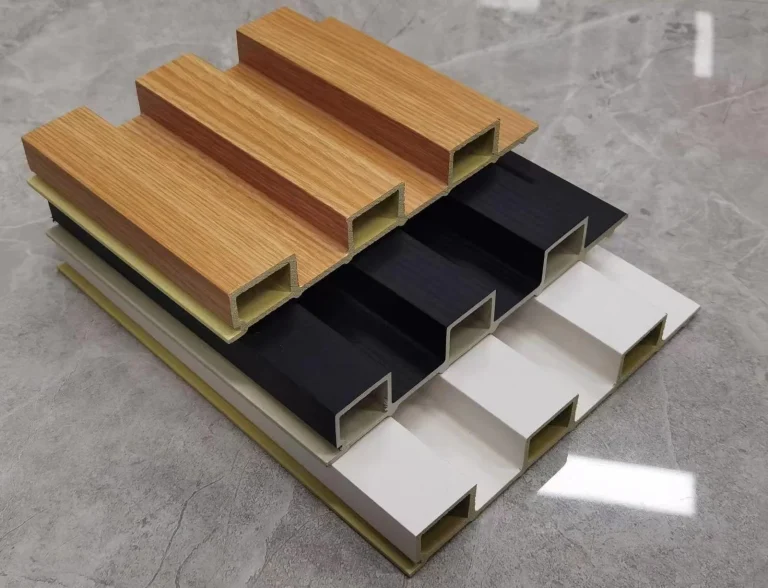

UV boards are quite popular due to their nature and because they bring more advantages than other materials used today. The boards are produced with a UV coating technology that ensures they have the best appearance and use possible. They are known to possess a smooth finish that emits a high-class ambiance. The reflective outside not only gives them a great look but also provides an easy process of cleaning and maintenance.

UV boards are also notoriously resistant to ageing due to scratches and staining, and have excellent moisture exposure performance. Which means they are absolutely the most popular choice for uses, like furniture pieces or wall coverings where durability is the only consideration! And come in a tremendous number of colors and designs to please different sensibilities and interior decorating aesthetics.

How UV Coating Enhances Durability

The durability of UV boards is due to the use of UV coating in their manufacture. The method exposes the surface to sunlight to form a resilient covering layer. The coating also makes the board considerably resistant to scratches and impacts.

The durability of UV boards is due to the use of UV coating in their manufacture. The method exposes the surface to sunlight to form a resilient covering layer. The coating also makes the board considerably resistant to scratches and impacts.

Moreover, the UV coating ensures that there will be no deterioration through artificial light or sunlight. As a result, UV boards are capable of being used for well-lit spaces. Finally, the covering acts to protect the boards from water so the boards will not warp or swell in the future.

How Do UV Boards Compare to Traditional Alternatives?

Differences Between UV Boards and Laminate Boards

In design, material like laminate boards and UV boards differs radically since they serve diverse purposes and appeal to diverse tastes and requirements.

UV panels also have a finish that contributes to their upscale look compared to laminate panels that will be more inclined to have a semi-gloss or matte finish instead. The smooth surface of the UV panels gives them a more sophisticated look. Also needs special attention to prevent noticeable fingerprints or smudges.

In comparing the lifespan of laminate boards and UV boards, UV boards are used because they can withstand scratches and water. Laminate boards delaminate or peel when subjected to water or high humidity for a prolonged period of time. UV boards retain strength and quality under extreme conditions.

Though laminate boards are generally not cheaper than UV boards, they are a low-budget option for budget projects. They also have varying textures and finishes unlike the shine of UV boards.

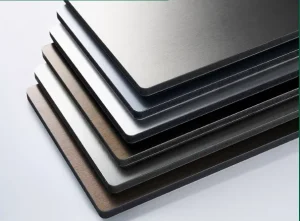

Comparing UV Boards with Acrylic Boards

Consider boards to be an inexpensive alternative to use indoors aside from UV boards, due to their glossy finishes and wide assortment of vibrant colors they are available in. UV boards tend to be able to provide scratch resistance over acrylic boards because their scratch-resistant outer finish layer coat resists scratches more consistently over the duration. Acrylic surfaces are susceptible to being scratched, and it can be refurbished to its shiny state by polishing if it gets damaged.

Are There Any Limitations to Using UV Boards?

Common Issues with UV Boards in Daily Use

UV boards, although highly useful for most applications, are not without some limitations. They are UV-stable, thus resistant to fading from sunlight, but an applied coat that stops this fading can be removed if the board is exposed to harsh environments or subjected to repeated abrasion. The finish then becomes less glossy and shorter-lived.

UV boards, although highly useful for most applications, are not without some limitations. They are UV-stable, thus resistant to fading from sunlight, but an applied coat that stops this fading can be removed if the board is exposed to harsh environments or subjected to repeated abrasion. The finish then becomes less glossy and shorter-lived.

They are also restricted in their stiffness. UV boards, although versatile, cannot be as flexible as other boards, making them more difficult to install, particularly in complicated or awkward places. They are waterproof, too, but excessive water or weather exposure can sometimes lead to warping or weakening.

Factors That May Affect the Longevity of UV Boards

The durability and appearance of UV boards also rely on factors such as the quality of UV coating on them, which determines how long-lasting and resistive they become for damage and deterioration.

The durability of UV boards is also decided to a great extent by factors. Higher humidity or longer exposure to water may make them weaker in the long term, unless their edges are sealed. Though UV boards are moisture-resistant to a certain extent, longer exposure can result in swelling or delamination problems.

How you care for them also decides how long they will last. Avoid using harsh cleaners since they will ruin the reflective surface and make it lose its brilliance and use instead soft cloths and gentle cleaners to keep the surface in good shape without scratches or spots.

Why Choose a Procurement Agent Like Sangni for UV Board Needs?

The Benefits of Working with Sangni as a Procurement Partner

When you look for materials, such as UV boards for your use or needs, you need to be careful and careful in selection so that you guarantee quality standards and maximize reliability and cost-efficiency. If you are looking for UV boards, Sangni is a choice since it is a supplier partner that offers better procurement services. Being procurement experts, we offer benefits that maximize and simplify the procurement process for you.

When you look for materials, such as UV boards for your use or needs, you need to be careful and careful in selection so that you guarantee quality standards and maximize reliability and cost-efficiency. If you are looking for UV boards, Sangni is a choice since it is a supplier partner that offers better procurement services. Being procurement experts, we offer benefits that maximize and simplify the procurement process for you.

Hiring Sangni provides you with an advantage due to our wealth of experience in being able to handle the supply chain in the right and efficient manner. Our connections with manufacturers ensure that we produce UV boards of high quality standards such that you receive products that meet your requirements while also being strong and having appealing looks.

How Sangni Simplifies the Sourcing Process for Clients

Sourcing UV boards from suppliers and managing different product specifications can be quite a task to handle on your own. However, Sangni simplifies this by serving as a primary contact for all your procurement requirements.

To start with, your project needs to be in mind, which involves looking into the dimensions you’re after as well as the finishes and colors you prefer for UV boards. Reaching out to such information helps us in using our understanding of the market to find manufacturers that can meet your expectations through their products. With Sangni, we take care of the negotiation process on your behalf effectively, utilizing our experience and market insight to negotiate prices without undermining the quality standards. On completion of the order, we move into overseeing production schedules and logistics management to provide timely delivery.

Our entire process not only saves time but also minimizes the chances of delay or errors in the buying process, and you can focus on other parts of the project while leaving us to obtain the best UV boards.

Ensuring Quality and Reliability Through Sangni’s Services

Sangni’s procurement services prioritize quality assurance as an aspect of their operations. We acknowledge the need for the UV boards to adhere to standards so that they can deliver maximum performance in different applications, ranging from furniture production to wall paneling projects.

During the production process, Sangni checks quality at points to ensure compliance standards, such as checking for even finish and color and strength testing to avoid defects, like delamination or warping.

By choosing Sangni as your UV board supplier, you will get products that undergo stringent quality screening. Our commitment to quality is such that each board you receive exceeds your expectations in both function and form.

Frequently Asked Questions about UV Board

Q: What is a UV board?

A: UV board refers to the type of material board, traditionally used in interior construction and design, where a substrate like MDF or plywood is overlaid with a UV-cured finish or lacquer. The process yields a high-gloss, wear-resistant surface with enhanced wear and moisture resistance.

Q: What are the disadvantages of UV board?

A: Total water resistance: UV MDF boards are not as water resistant as PVC boards, and not suitable for exposure to moist conditions in the long run. Greater cost: In comparison to normal MDF boards, UV MDF boards are costlier to produce and comparatively more expensive.

Q: What is the difference between UV and PVC sheets?

A: UV sheet is glossy in finish and can be utilized in any design. PVC sheet, on the other hand, is an inexpensive means of getting actual marble look which is easy to maintain and also long-lasting.