Why Are PE Wood WPC Boards So Popular?

Key Features That Differentiate PE-Based WPC Boards

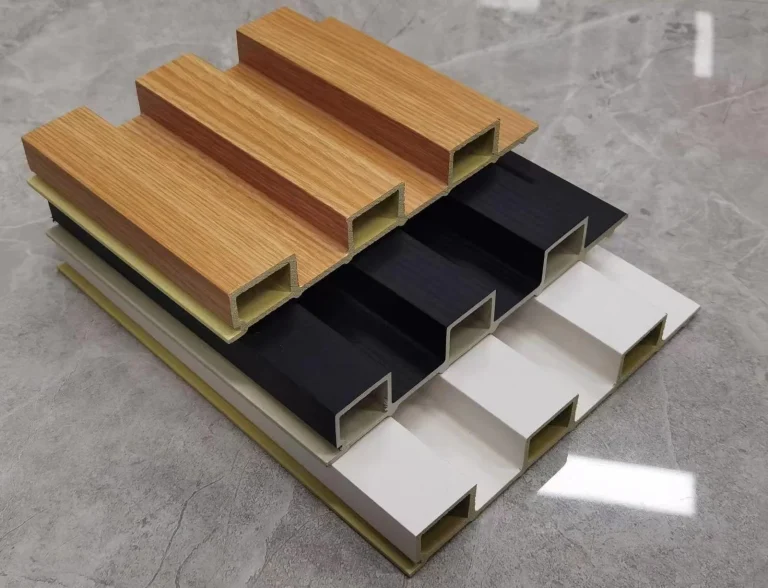

Polyethylene (PE) wood plastic composite (WPC) boards are a revolution in the building sector due to their configuration and unusual characteristics. The boards are produced by combining polyethylene with bamboo powder or wood powder through extrusion technique. By using the water-resistant and robust nature of plastic and the texture and appearance of wood, they can preserve wood’s own elegance but with strength.

Polyethylene (PE) wood plastic composite (WPC) boards are a revolution in the building sector due to their configuration and unusual characteristics. The boards are produced by combining polyethylene with bamboo powder or wood powder through extrusion technique. By using the water-resistant and robust nature of plastic and the texture and appearance of wood, they can preserve wood’s own elegance but with strength.

One unique characteristic is their capacity to endure weather conditions well, in contrast to other plastics. PE plastic wood composite showcases superior outdoor weather resistance (capable of enduring wind and sun exposure). Their surfaces can be altered to imitate wood grain or painted for protective purposes. In addition, Polyethylene-based Wood Plastic Composite boards are light in weight, simple to mold and waterproof, thus an adaptable choice for many applications.

The Advantages of Using PE in WPC Board Production

Polyethylene serves as the material for WPC boards and comes with a variety of benefits. During the production, extrusion methods help to get a structure and appearance for such boards. The boards are also designed to remain longer than 10 years on outdoor installation and are an efficient and economical method for long-duration performance specifications.

PE-based WPC boards are eco-friendly too as they contain waste plant fibers like bamboo powder and wood powder. It not only saves waste, but also reduces the use of conventional timber resources, ensuring sustainable construction practices. Moreover, the addition of additives during the manufacturing process enhances them to be stronger with higher scratch resistance, UV resistance, and durability.

How Do PE-Based WPC Boards Perform Compared to Other Materials?

Durability and Strength of PE-Based WPC Boards

From the aspects of durability and life, PE PE-based WPC boards are superior to conventional materials, like real wood or PVC-based composites. Wood plastic outside floors consist primarily of PE and wood powder or bamboo powder and form a pressure-resistant structure that will not crack, warp or split easily.

Moreover, their water resistance does not allow them to soak up water that may degrade materials, such as wood over time. Their natural strength is best suited for places, like garden settings or villa decks that have to withstand continuous load.

Resistance to Environmental Factors

One of the merits of PE-based WPC boards is that they are very weather-resistant. The flooring made from this material can be installed in outdoor areas, such as garden landscapes and villas since it can tolerate extreme weather conditions and yet maintain that it remains strong and attractive.

The PE-based WPC boards do not rot nor get infested by insects when they become damp or are subjected to humidity compared to wood products because they are water-resistant. They will also not change color even after extensive exposure to the sun because they are UV-resistant.

What Applications Make PE-Based WPC Boards a Preferred Choice?

Common Uses in Construction and Interiors

PE-WPC boards are currently trendy in construction and interior design business because they are efficient in performance and versatility. Wood plastic outside decking consists primarily of PE mixed with wood powder or bamboo powder, and it can be formed into sizes and shapes to suit different applications.

PE-WPC boards are currently trendy in construction and interior design business because they are efficient in performance and versatility. Wood plastic outside decking consists primarily of PE mixed with wood powder or bamboo powder, and it can be formed into sizes and shapes to suit different applications.

They have broad uses in construction on horizontal surfaces, including backyard patios and garden landscapes, due to the fact that they are resistant to abusive conditions and can therefore be used for such types of applications. They can also be used on fences and privacy walls as well as on swimming pool decks where moisture resistance is important.

In interiors, PE-based WPC boards are an excellent replacement for natural wood. They have wide-ranging uses in wall panels, grid panels and wood veneers. Since they are light in weight and easy to shape, designers can impart shapes to them in intricate patterns without losing out on the structural strength.

Benefits for Long-Term Usage in Specific Projects

PE-based WPC boards are renowned for their durability since they can last more than a decade when fitted outside without ever losing their quality and durability. It is this property of resisting deterioration that makes them a rational decision for use where materials are needed, which will be able to endure weathering and extensive usage without showing even the slightest trace of wear. In places with foot traffic, such as public areas or business establishments, the board’s resistance to cracking and warping helps their usage and looks to last longer.

How Can Sangni Help You Source High-Quality PE-Based WPC Boards?

Our Role as a Reliable Procurement Agent

Here at Sangni, our main objective is to serve as a middleman for purchasing needs and connect buyers with better manufacturers of PE-based high-grade WPC boards. Employing our experience and vast network in the industry, we make sure that buyers receive products of quality standards.

We manage the procurement process from the first stage of negotiations to the final stage of delivery, where we also check the quality of raw materials used in production processes. We focus on ensuring that used materials have a lifespan outdoors of more than 10 years to provide long-term reliability to projects that need long-lasting materials. Our keen eye ensures that each batch of materials we buy meets the specifications provided by our clients.

Why Choose Sangni for Your Procurement Needs

Opt for Sangni as your procurement ally, you will be blessed with the benefits it has in store for you! Our strong determination towards upholding quality standards means that you’ll be receiving notch PE-based WPC boards specifically customized to your precise requirements and specifications. Grasping the significance of durability and aesthetic value in construction projects pushes us to procure materials that are high on both these counts simultaneously.

Other than that, we assist you with the entire process of purchasing goods and services for your business needs. We assist in decision-making for the product specifications and manage the shipment arrangements to deliver goods on time. Our team guarantees a smooth process. Our deep understanding of market trends allows us to suggest solutions that are suited to your project objectives and help you save money successfully.

Frequently Asked Questions about PE Wood Plastic Composite Board

Q: What is PE composite decking?

A: PE composite decking is an exterior decking product made from wood fibers and polyethylene (PE) plastic. It’s very common as an alternative to traditional wood decking because it’s extremely durable, low maintenance, and rot, decay, and insect resistant.

Q: What is Wood Plastic Composite board?

A: Wood plastic composite (WPC) is a newly emerged composite material which contains natural plant fibers, i.e., wood, bamboo and hemp, and thermoplastic, i.e., polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) etc.

Q: What is the difference between WPC and HPC?

A: HPC products are less water-absorbing, more tightly grip nails, and deform/warp less than traditional wood-plastic composite material (WPC).

Q: Is composite decking wood or plastic?

A: A lot of folks get plastic mixed up with composite decking, but there’s a couple of differences. Composite boards are made by combining polymers and real wood, so they’re hybrid, or ‘semi-synthetic’ if you’d like to label it that.